IntroductionDesigned with longevity in mind, electric motors are made to function safely, economically, and perpetually. In theory, proper care and use of these components will ensure many years of successful operation. However, the real world is a different story, where motors are subjected to numerous environmental and operational hazards that cause thermal stress on the windings. Thermal stresses degrade the insulation quality of the motor, thereby diminishing its life expectancy.

That is why monitoring the operating condition of motors has become such an important aspect of predictive maintenance programs. With electric motor testing we can monitor and trend the condition of AC induction, synchronous, wound rotor, DC motors, and their circuits. Testing capabilities are:

• Power Quality

• Power Circuit

• Stator

• Rotor

• Insulation

• Air gap Problems Why Use Thermography?• Safe

• Fast

• Increased Reliability

• Prevent Outages

• Real Time Analysis

• Compact

• Cost effective

• Document and Trend

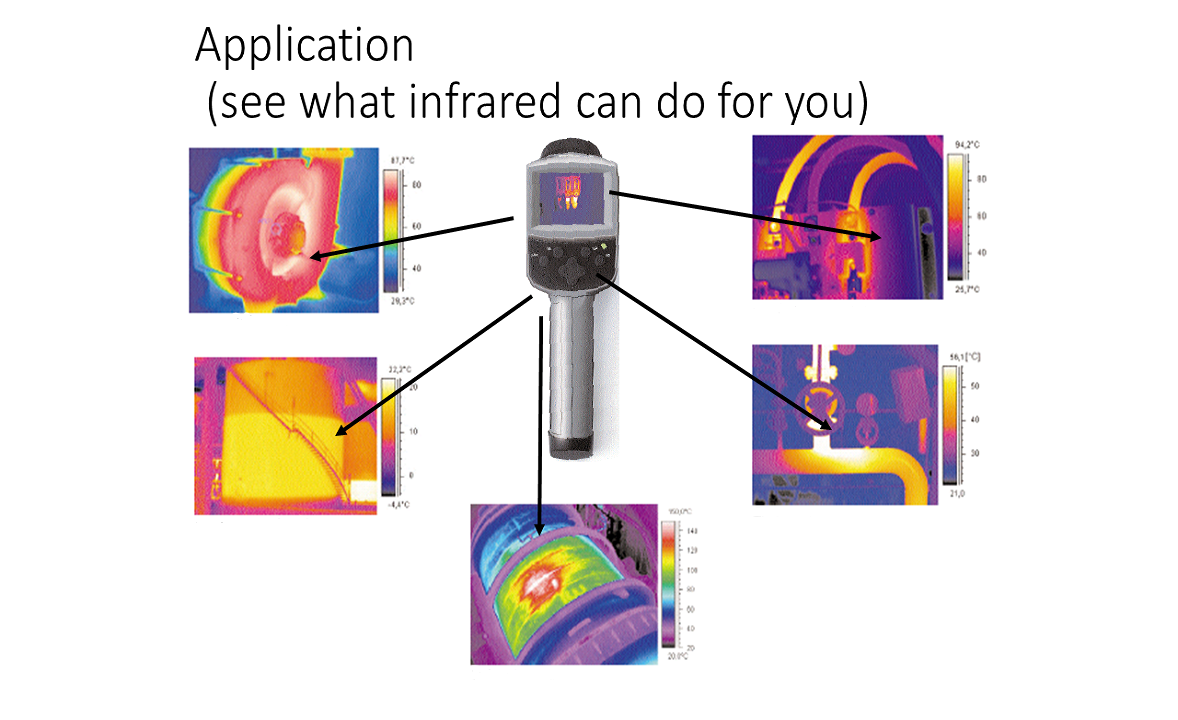

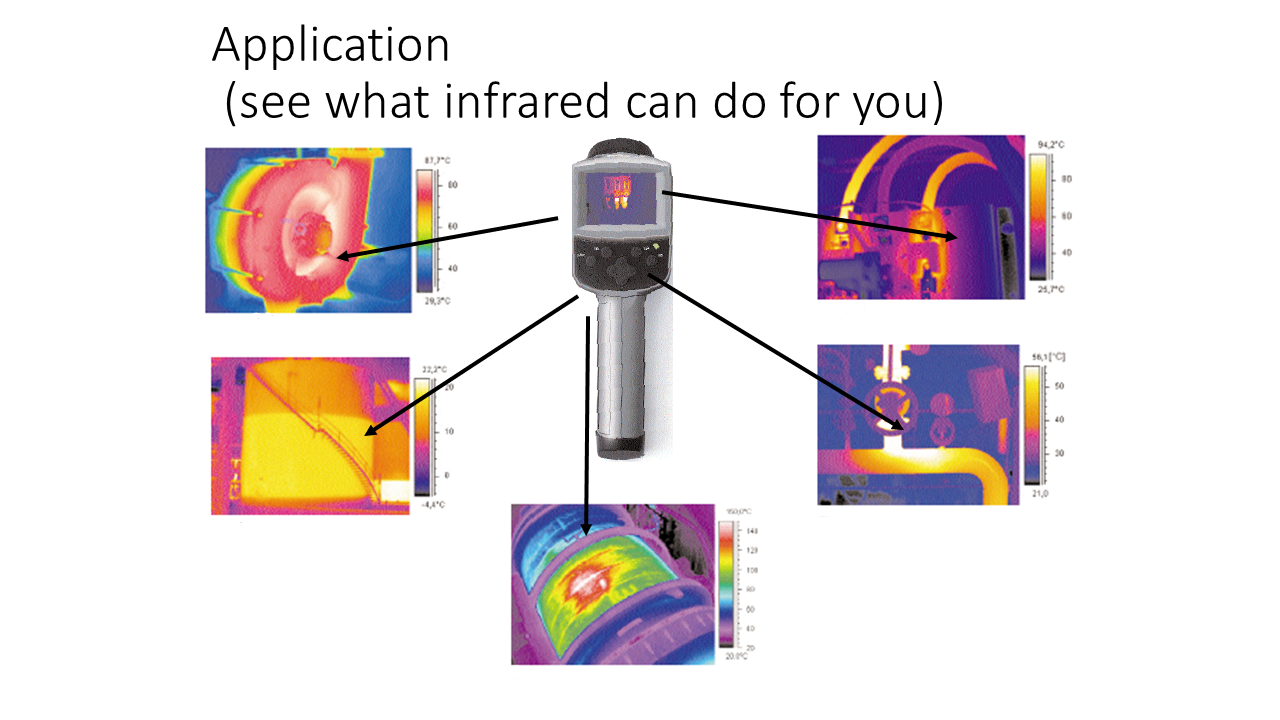

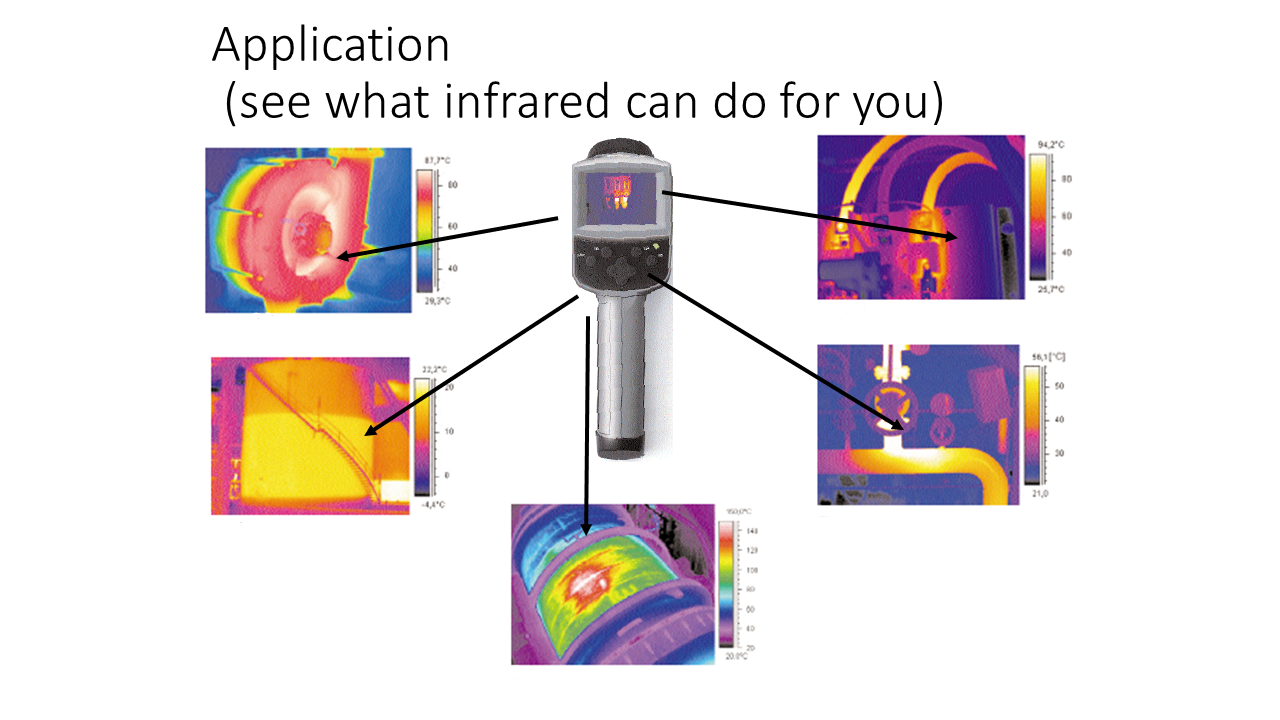

Applications• Bearings

• Motor Casings

• Internal Windings

• Power Transmission Train - Gears, Belts, Couplings

Why Use Thermography?• Safe

• Fast

• Increased Reliability

• Prevent Outages

• Real Time Analysis

• Compact

• Cost effective

• Document and Trend

|

|